Posted February 4, 2013 by Nicole Belanger

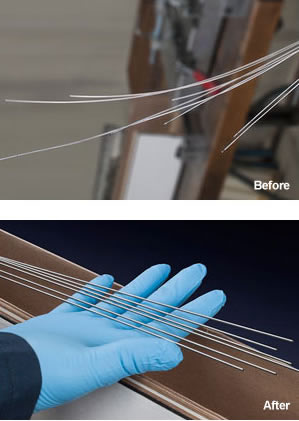

New Tube Straightening Equipment Ensures Elimination of Bowing Problems

MicroGroup’s All-Tube Division continues to invest in its manufacturing platform with the addition of a new, custom made tube straightening machine. With the increased sophistication of medical devices and various types of instrumentation, tubing that was once considered “commercially acceptable” no longer meets the grade. This new piece of equipment enhances All-Tube’s ability to prevent bowing that may cause problems further into the product development cycle.

MicroGroup’s All-Tube Division continues to invest in its manufacturing platform with the addition of a new, custom made tube straightening machine. With the increased sophistication of medical devices and various types of instrumentation, tubing that was once considered “commercially acceptable” no longer meets the grade. This new piece of equipment enhances All-Tube’s ability to prevent bowing that may cause problems further into the product development cycle.

Said William Bergen, President & CEO of MicroGroup, Inc., “We recognize that we have to be able to quickly straighten industrial tubing to tight tolerances in order to meet the increasing demands of our customers. This investment demonstrates our continued commitment to ensure we deliver on our core focus areas of Speed and Precision.”

Highlights of the Custom Build Straightener include:

- Ideal for stainless steel grades and nickel based allows (Nickel 200 and Inconel® 600 Alloy)

- Tolerance of 0.030″ per 3 feet maintained

- Maximum efficiency with longer length tubing

- Superbly engineered machine produces jobs fast as needed