Abrasive Cutting

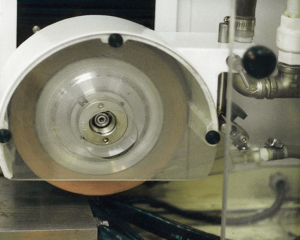

Abrasive cutting is less precise than other methods offered by MicroGroup, but is often selected on the basis of cost when parts do not require high precision or strict edge condition requirements, or when other methods are ineffectual. Abrasive cutting can typically maintain length tolerances of ±.010″, but can be held to ±.005″ or better on some smaller diameter, shorter length parts. Blades of different thicknesses and grits can be selected and spindle speeds can be varied to optimize surface finishes, depending on the alloy and size of the material being cut.

Abrasive cutting is less precise than other methods offered by MicroGroup, but is often selected on the basis of cost when parts do not require high precision or strict edge condition requirements, or when other methods are ineffectual. Abrasive cutting can typically maintain length tolerances of ±.010″, but can be held to ±.005″ or better on some smaller diameter, shorter length parts. Blades of different thicknesses and grits can be selected and spindle speeds can be varied to optimize surface finishes, depending on the alloy and size of the material being cut.

Some ferrous and non-ferrous materials that cannot be cut using other conventional methods can be cut readily using abrasive cutting. These materials include ceramics, composites, refractory metals, carbides and hard steels. Generally, abrasive cutting is unsuitable for large diameter and/or thick wall materials, as prolonged contact of the blade with the workpiece can generate friction that ‘burns’ the material.