Posted December 18, 2013 by Nicole Belanger

MicroGroup “Cleans-Up” with Extensive In-House Cleaning and Surface Finishing Capabilities

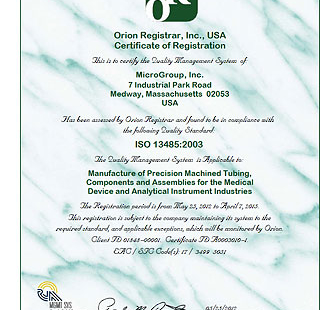

MicroGroup, Inc., a leading supplier of tubing materials and manufacturer of precision metal components and assemblies, continues to enhance and expand its world-class cleaning and surface finishing capabilities. MicroGroup’s broad range of validated cleaning and finishing services offers customers consistent quality, attractive value and the supply chain ease of a single point of contact. Detailed below are general listings of MicroGroup’s cleaning and surface finishing capabilities, however, for more in-depth descriptions, go to our capabilities page..

MicroGroup, Inc., a leading supplier of tubing materials and manufacturer of precision metal components and assemblies, continues to enhance and expand its world-class cleaning and surface finishing capabilities. MicroGroup’s broad range of validated cleaning and finishing services offers customers consistent quality, attractive value and the supply chain ease of a single point of contact. Detailed below are general listings of MicroGroup’s cleaning and surface finishing capabilities, however, for more in-depth descriptions, go to our capabilities page..

Surface Finishing

- Micro Grit Blasting

- Electro Polishing

- Vibratory Polishing

- Passivation (recently acquired ESMA E992 Self-Contained Passivation System)

- Lapping

- Tumbling

- Manual Deburring

- ID Honing

- Centerless Grinding

- And more

Cleaning

- Vapor Degreasing

- Ultrasonic Cleaning

- Pickling/Acid Etching

- Deionized Water Rinsing

- And more

Said William Bergen, President and CEO of MicroGroup, Inc., “Surface finishing and cleaning are areas where we have invested substantial engineering resources and capital investment over the last several years to enable our customers to meet their increasing demands.”