Posted September 13, 2013 by Nicole Belanger

MicroGroup Offers World Class CNC Milling Capabilities

When Speed and Precision Count

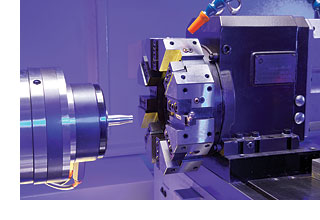

MicroGroup is renowned for its inventory of 7,000,000 feet of small diameter tubing with a diverse and extensive manufacturing platform. However, did you know that MicroGroup has in its two state-of-the-art facilities, 25 multi-axis (up to 5 axis) CNC milling machining centers (horizontal and vertical) with the center of excellence being its Twin Cities facility? This large production capacity is an ideal opportunity for OEMs from Medical Device, Aerospace, Industrial and other markets to ramp up their speed to market (prototypes and production runs) and get a jump on the competition. Moreover, the variety of configurations of the machines including dedicated manufacturing cells will assure that the best fit milling center is used for the particular requirements of a job, keeping costs down.

MicroGroup is renowned for its inventory of 7,000,000 feet of small diameter tubing with a diverse and extensive manufacturing platform. However, did you know that MicroGroup has in its two state-of-the-art facilities, 25 multi-axis (up to 5 axis) CNC milling machining centers (horizontal and vertical) with the center of excellence being its Twin Cities facility? This large production capacity is an ideal opportunity for OEMs from Medical Device, Aerospace, Industrial and other markets to ramp up their speed to market (prototypes and production runs) and get a jump on the competition. Moreover, the variety of configurations of the machines including dedicated manufacturing cells will assure that the best fit milling center is used for the particular requirements of a job, keeping costs down.

- Particular strengths include complex, tight tolerance parts in small to medium volumes (10-10,000 month)

- Extensive live tooling and auto pallet loading capabilities for delivering compelling value

- MicroGroup’s EDM, Swiss turning, grinding, laser, welding/assembly, and finishing capabilities provide additional value added capabilities

- MicroGroup’s Boston, MA and Twin Cities, MN facilities are ISO 9001 and ISO 13485 Certified

Said William Bergen, President and CEO of MicroGroup, Inc., “One of our largest opportunities is we consistently hear from customers, ‘We didn’t know you could do that.’ This communication is part of our efforts to do a better job talking to our current and potential customers about how our focus on Speed and Precision combined with our broad set of in-house capabilities can deliver superior value to them.”